WELCOME

“tool-kit PROFESSIONAL ... the software solution for experts”

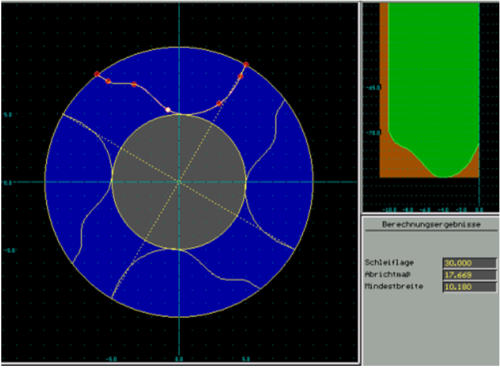

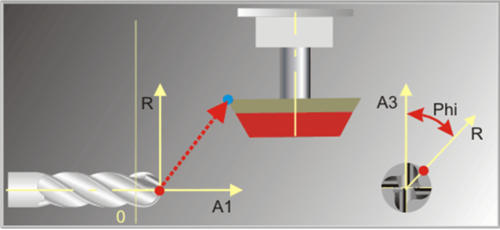

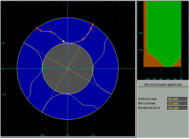

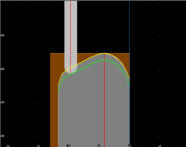

17.1 Flute Construktion / Profil Wheel Calculation

•

Construction of Flute Profile:

•

Construction by integr. CAD

•

Calculation of wheel-profile

•

Calculation of grinding track

•

Intersection simulation

•

Output of wheel discription

•

CAD-Program specilized to the usage of tool-construction including interface

to the grinding-modules.

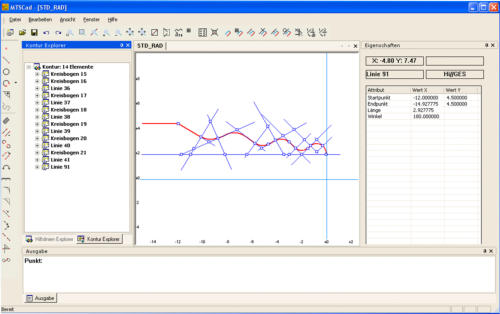

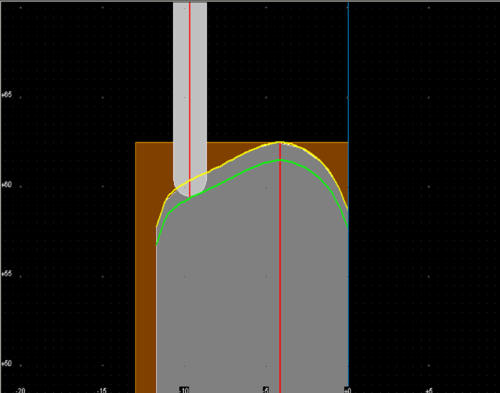

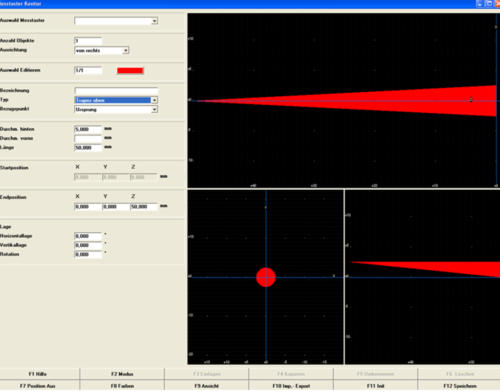

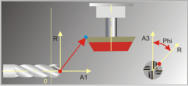

19.1 Dressing

18.1 CAD Modul

20.1 Open Procedure

•

Wheel dressing:

•

Construction and generating of selfmade additional operations. Integration

at any operation-position

•

Graphical construction of open procedures

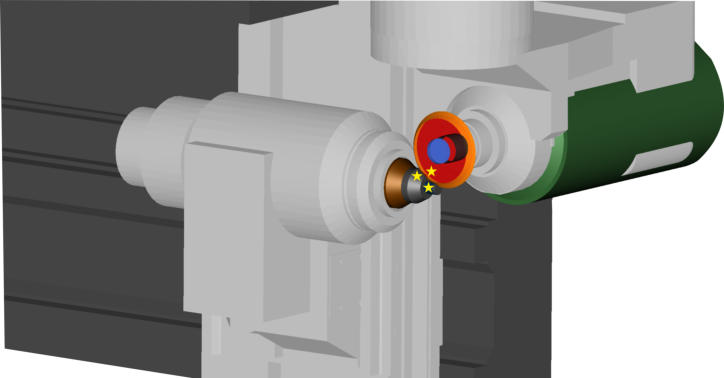

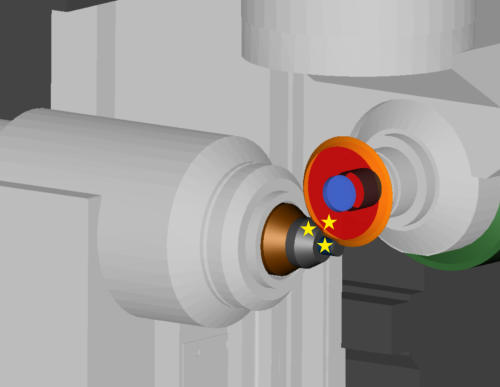

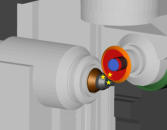

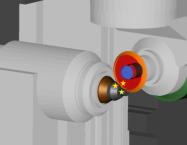

21.1 Collison Control

23.1 Measurement-Cycles

•

Functions:

NC_start without collision-control

NC_start with collision-control and auto-stop at first collision.

NC_start with collision-control and collision protocoll of all situations

NC_simulation without collision display

NC_simulation with collision display

•

Extended CNC-Generator:

Collision-control: Yes / No

Mode-selection:

„Stop at first collision“ / “All collisions“

•

Mode „Stop at first collision“:

The

modul

stops

the

calculation

of

the

CNC-code

by

recognition

of

the

1st

collision and shows these graphically on the scope.

•

Mode „All collisions“:

First

the

CNC

code

will

be

calculated

completely.

Subsequently

we

will

have

a listing of all collision situations.

In the following these can be individually plotted and examined.

•

Administration of the collision objects (Setup):

4 object lists:

Basical objects, tool-objects, clamping- and spindle-objects.

The list administration takes place in each case by inserting, copying,

renaming or deleting. The selection of the objects which

can be considered concerning the

collision takes place via activating in the object lists

•

Collision calculation:

Examinating the penetration of all activated objects, as well as the active

grinding wheel outside of the workpiece.

Generating the collision protocol

•

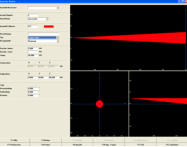

Measurement-Cycles for 3D-probing-system

Length

Tooth positioning

Helix lead (cylindrical, conical)

Diameter (cylindriical, conical)

Teeth-indexing

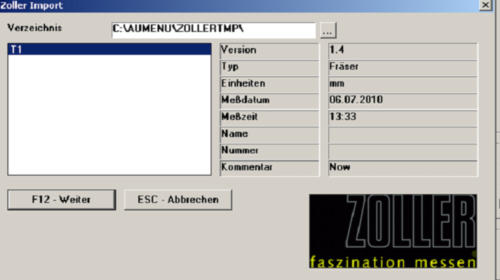

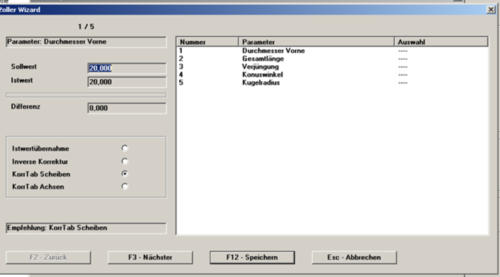

24.1 Measurement-Machine

•

Interface within tool-kit PROFESSIONAL to a measurement-maschine

(Exp. Zoller genius 3).

•

Measurement-data will be read and analysed by the error-handling-

procedure.

•

The generated correction-data will be used in ordert to come to correct

must values at next grinding step.

•

Correction Options:

•

Correction on the wheel data:

•

Reasonable corrections f.e. at diameter, rake-angle and wheel-distance.

•

Using the operation-specifical correction table:

•

Corrections at machine-data or wheel-data.

•

Correction of tool parameter:

•

Correction in inverse direction to the actual value and setpoint.

“tool-kit PROFESSIONAL ... the software solution for experts”

ADRESS

Rheinstrasse 81

CH-4133 Pratteln

Switzerland

Copyright © 2001- 2024 MTS AG

Made with MAGIX

OPTIONS

VORLAGE

17.1 Flute Const. / Profil Wheel Calc.

18.1 CAD Modul

19.1 Dressing

20.1 Open Prodedure

22.1 Collison-Controll

23.1 Measurement-Cycles

23.1 Measurement-Machine

Galerie

•

Interface within tool-kit

PROFESSIONAL to a

measurement-maschine

(Exp. Zoller genius 3).

•

Measurement-data will be read and

analysed by the error-handling-

procedure.

•

The generated correction-data will

be used in ordert to come to correct

must values at next grinding step.

•

Correction Options:

•

Correction on the wheel data:

•

Reasonable corrections f.e. at

diameter, rake-angle and wheel-

distance.

•

Using the operation-specifical

correction table:

•

Corrections at machine-data or

wheel-data.

•

Correction of tool parameter:

•

Correction in inverse direction to the

actual value and setpoint.

•

Functions:

NC_start without collision-control

NC_start with collision-control and

auto-stop at first collision.

NC_start with collision-control and

collision protocoll of all situations

NC_simulation without collision

display

NC_simulation with collision display

•

Extended CNC-Generator:

Collision-control: Yes / No

Mode-selection:

„Stop

at

first

collision“

/

“All

collisions“

•

Mode „Stop at first collision“:

The

modul

stops

the

calculation

of

the

CNC-code

by

recognition

of

the

1st

collision

and

shows

these

graphically on the scope.

•

Mode „All collisions“:

First

the

CNC

code

will

be

calculated

completely.

Subsequently

we

will

have

a

listing

of

all

collision

situations.

In

the

following

these

can

be

individually plotted and examined.

•

Administration of the collision

objects (Setup):

4 object lists:

Basical objects, tool-objects,

clamping- and spindle-objects.

The list administration takes place in

each case by inserting, copying,

renaming or deleting. The selection

of the objects which

can be considered concerning the

collision takes place via activating in

the object lists

•

Collision calculation:

Examinating the penetration of all

activated objects, as well as the

active grinding wheel outside of the

workpiece.

Generating the collision protocol

•

Measurement-Cycles for 3D-

probing-system

Length

Tooth positioning

Helix lead (cylindrical, conical)

Diameter (cylindriical, conical)

Teeth-indexing

•

Construction and generating of

selfmade additional operations.

Integration at any operation-

position

•

Graphical construction of open

procedures

•

Wheel dressing:

•

CAD-Program specilized to the

usage of tool-construction including

interface to the grinding-modules.

•

Construction of Flute Profile:

•

Construction by integr. CAD

•

Calculation of wheel-profile

•

Calculation of grinding track

•

Intersection simulation

•

Output of wheel discription

“tool-kit PROFESSIONAL ... die Software für den Profi”

OPTIONS