WELCOME

“tool-kit PROFESSIONAL ... the software solution for experts

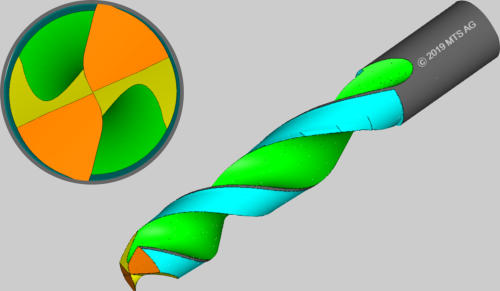

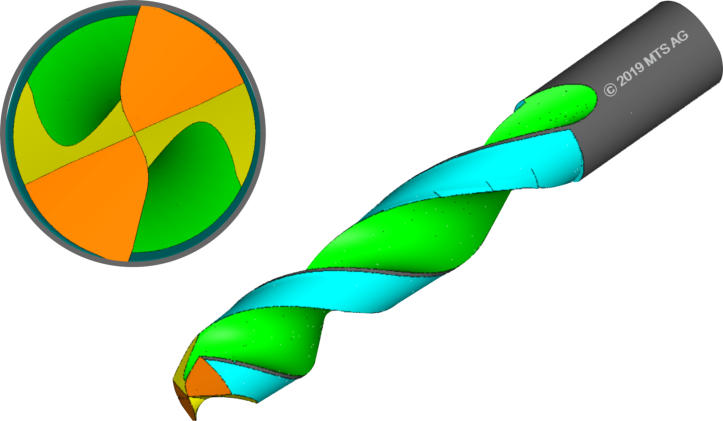

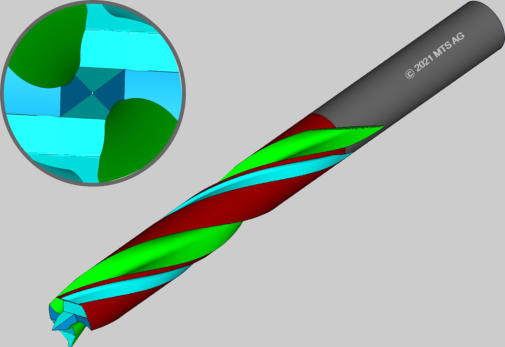

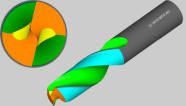

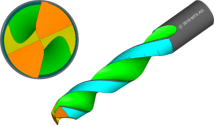

6.1 Basic Modul Drills (BMENU)

Optionen

•

Work Piece:

2 or 3 teeth

1 – 5 Steps

•

Cutting Edge Combination:

right helix/right cut

left helix/left cut

•

Produktion / Regrinding:

Production by different infeed (several steps)

•

Regrinding with calculation of removal

ength, periphery and rake.

•

Regrinding, finishing with different wheels

•

Point:

Standard

Split point

2-facet point

4-facet point

6-facet point

Delta – point

M – point

Kevlar – point

Centring point

Milling end face

•

2

nd

Chamfer:

Optional: 2

nd

chamfer

•

1

st

Web Thinning:

Correction of main cutting edge

Correction of chisel edge

S-web thinning (incl. Sumitomo like)

Free constructed notchings / corrections

•

2

nd

Web Thinning:

Correction of main cutting edge

Correction of chisel edge

•

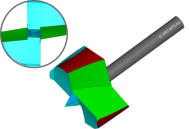

Main Fluting:

Meas. definition: Point-/ normal cut

Grind. direction: Forward / backward

Optional spark out grinding

Separated fluting per step

•

Periphery:

Radial grinding / Round grinding

Transverse/longitudinal positioning

Linear relief: 1./2. relief angle

•

Steps:

Standard step (axial/radial relief angle)

Step aperture angle: 45 - 200°

Linear relief step (aperture angle 170°)

•

Chip Breaker:

1 or 2 chip breakers per tooth

•

Simulation

Simulation of intersection at all operations

Wheel/workpiece-simulation

Machining simulation

•

Production from standard- to step drill:

Special measurement and calculation program

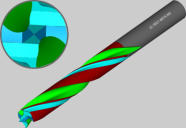

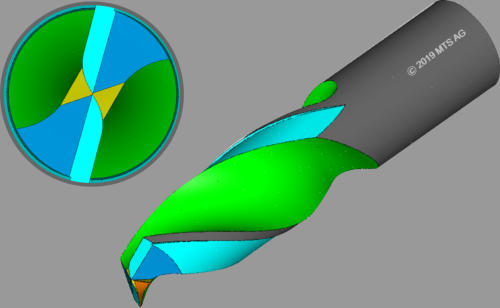

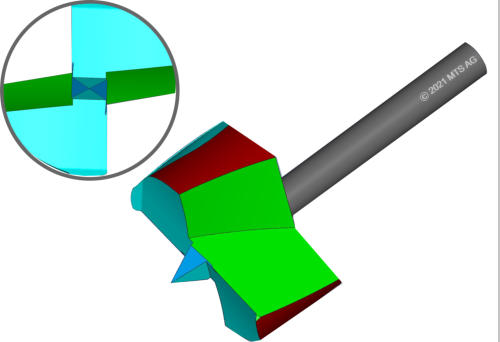

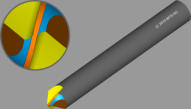

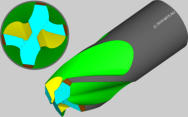

6.2 Subland Drills

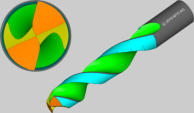

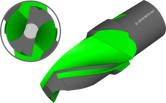

6.3 S-Point

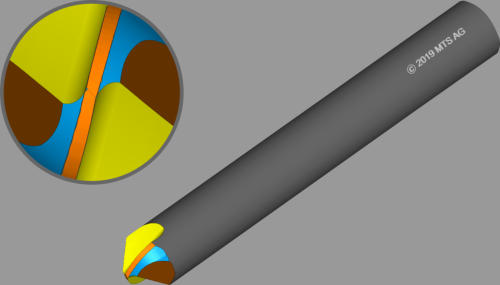

6.4 Woodworking tools

Galerie

•

Specification according to Standard-/Stepping Drills Secondary Fluting

•

Defined rotation against main fluting

•

Tool: 6010017 „Subland drill“

•

Tool: 6050017 „Radius drill (Gühring KG)“

•

Exclusive Gühring KG

•

Tool: 6060017

•

Basic modul

•

Tool: 6070017

•

Basismodule

•

Tool: 6080017 „Dowel drill“

•

Basic modul + option woodworking tools

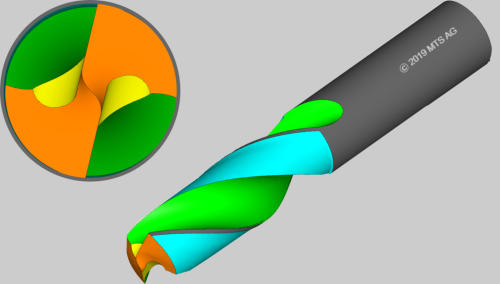

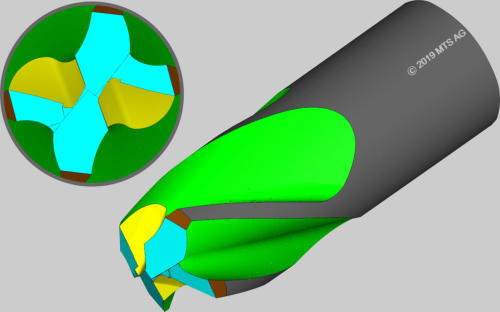

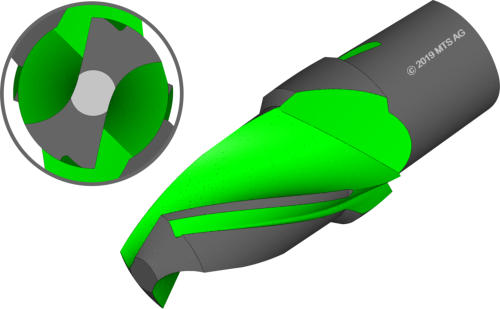

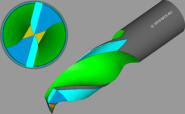

6.5 MTS-GIGA-Drill

•

S-Point:

2- and 3-teeth

•

Tool 6020017 „Drill S-Point“

•

Drill for woodworking:

•

Pin-drill

•

Forstner-Drill

•

Tool: 6030017

•

Special point with 4 teeth / flutes:

•

The two-stepped Giga-Drill is like a typical subland-drill-geometry.

•

Tool 6040017 „GIGA-Drill“

“tool-kit PROFESSIONAL ... the software solution for experts”

ADRESS

Rheinstrasse 81

CH-4133 Pratteln

Switzerland

Copyright © 2001- 2024 MTS AG

Made with MAGIX

MODUL DRILLS

VORLAGE

Galerie

•

Tool: 6050017 „Radiusbohrer

(Gühring KG)“

•

Exclusive Gühring KG

•

Tool: 6060017

•

Basic Modul

•

Tool: 6070017

•

Basic modul

•

Tool 6080017

•

Basic modul + option woodworking tools

1.1 Basic Modul Drills (BMENU)

Optionen

6.2 Subland Drills

•

Specification according to Standard-

/Stepping

Drills Secondary Fluting

•

Defined rotation against main fluting

•

Tool: 6010017 „Subland drill“

6.3 S-Point

6.4 Woodworking Tools

•

S-Point:

2- and 3-teeth

•

Werkzeug: 6020017

6.1 Basic Drills + 6.3 S-Point

•

Drills for woodworking:

•

Pin-Drills

•

Forstner-Drill

•

Tool: 6030017

6.5 MTS-GIGA-Drill

•

Special point with 4 teeth / flutes:

•

The two-stepped Giga-Drill is like a

typical subland-drill-geometry.

•

Tool: 6040017 6.1 Basic Drillsr + 6.5

GIGA

•

Work Piece:

2 or 3 teeth

1 – 5 Steps

•

Cutting Edge Combination:

right helix/right cut

left helix/left cut

•

Produktion / Regrinding:

Production by different infeed

(several steps)

•

Regrinding with calculation of

removal

ength, periphery and rake.

•

Regrinding, finishing with different

wheels

•

Point:

Standard

Split point

2-facet point

4-facet point

6-facet point

Delta – point

M – point

Kevlar – point

Centring point

Milling end face

•

2

nd

Chamfer:

Optional: 2

nd

chamfer

•

1

st

Web Thinning:

Correction of main cutting edge

Correction of chisel edge

S-web thinning (incl. Sumitomo like)

Free constructed notchings /

corrections

•

2

nd

Web Thinning:

Correction of main cutting edge

Correction of chisel edge

•

Main Fluting:

Meas. definition: Point-/ normal cut

Grind. direction: Forward / backward

Optional spark out grinding

Separated fluting per step

•

Periphery:

Radial grinding / Round grinding

Transverse/longitudinal positioning

Linear relief: 1./2. relief angle

•

Steps:

Standard step (axial/radial relief

angle)

Step aperture angle: 45 - 200°

Linear relief step (aperture angle

170°)

•

Chip Breaker:

1 or 2 chip breakers per tooth

•

Simulation

Simulation of intersection at all

operations

Wheel/workpiece-simulation

Machining simulation

•

Production from standard- to step

drill:

Special measurement and

calculation program

“tool-kit PROFESSIONAL ... die Software für den Profi”

CONTACT

info(at)mtsag.net

Phone: +41 61 81 59 130

whatsapp: +41 78 62 77 560

Fax: +41 61 81 59 139

ADRESS

Rheinstrasse 81

CH-4133 Pratteln

Switzerland

MODUL DRILLS