WELCOME

“tool-kit PROFESSIONAL ... the software solution for experts”

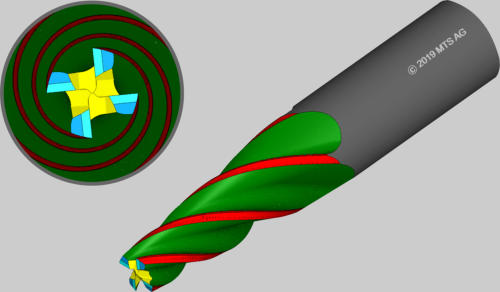

1.1 Basic Modul Endmills (FMENU)

Option

•

Workpiece:

Cylinder

Taper

Angular Cutter

•

Point:

Plan Face

Chamfer

Corner Radius

Ball Nose

Circular Arc

Double Radius

•

Geometry:

Regulare

2 at Center

1 above Center

Centring Point

3 at Center

•

Cutting Edge Combination:

right helix/right cutting

left helix/left cutting

right helix/left cutting

left helix/right cutting

•

Division:

Equal / unequal division of teeth

•

Production / Regrinding:

Production by different infeed (several steps)

Regrinding with calculation of removal

length, periphery and rake.

Regrinding, finishing with different wheels

•

Preparation

Separating

Profile roughing

Profile finishing

Main FlutingMeas.

definition: Point-/ normal cut

Grind direction: Forward / backward

Optional spark out grinding

•

Taper:

Constant angle / constant helix

Regrinding with undefined helix

•

Periphery

Linear relief: 1st/ 2nd /3rd relief angle

Radial relief: Cross-/ longitudinal

Roughing

Grind direction: Forward / backward

Optional spark out grinding

•

Heei:

Grind procedure: Crosswise-/ longitudinal

Production by different infeed (several steps)

Grind direction: Forward / backward

Optional spark out grinding

•

End Face

Linear relief grinding

Hollow grinding

•

Chamfer Clearance/Chamfer

Linear relief: 1st/ 2nd /3rd relief angle

Grind. direction: Forward / backward

Optional spark out grinding

•

Gashing

Grinding procedure:

Recessing / Interpolation

Radius at entry and exit

Variable aperture angle

•

Notching:

Radius at entry and exit

Variable entry- and aperture angle

•

Profile Simulation:

Simulation of intersection at all operations

Wheel/workpiece-simulation

Machining simulation

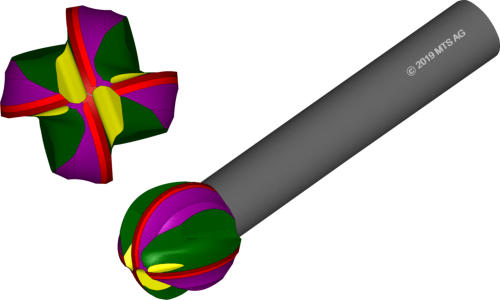

1.2 Ball:

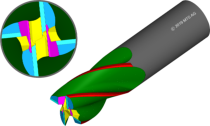

1.3 Variably Helix

1.4 Wavecut (Crest-cut)

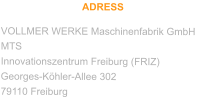

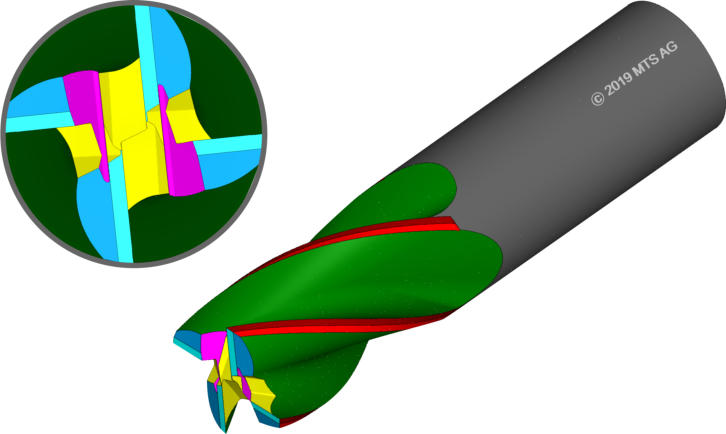

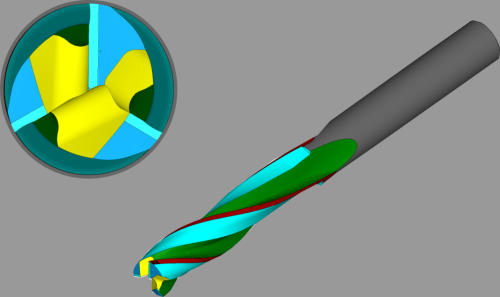

Galerie

•

Ball

•

Tool: 1010017 „Endmill Ball“

•

Variably Helix of Fluting:

•

Tool: 1040017 „Endmill Variably Helix“

•

Basic Modul + Option 1.3

•

Tool 1050017 „6-Cut with Chamfer“

•

Basic Modul

•

Tool: 1060017 „ Full radius 2 to center“

•

Basic Modul

•

Tool 1070017 „Taper tool“

•

Basic Modul

“tool-kit PROFESSIONAL ... the software solution for experts”

Copyright © 2001- 2025 MTS AG

Made with MAGIX

MODUL ENDMILLS

Open with Google Maps

CONTACT

Email:

Phone:

ADRESS

VOLLMER WERKE Maschinenfabrik GmbH

MTS

Innovationszentrum Freiburg (FRIZ)

Georges-Köhler-Allee 302

79110 Freiburg

VORLAGE

1.1 Basic modul Endmills (FMENU)

Option

1.2 Ball

1.3 Variably Helix

1.4 Wavecut (Crest-cut)

Galerie

•

Ball

•

Tool:1040017 „Endmill Variably Helix“

•

Basic Modul

•

Tool 1050017 „6-Cut with Chamfer“

•

Basic Modul

•

Tool: 1060017 „ Full radius 2 to center“

•

Basismodul

•

Tool 1070017 „Taper tool“

•

Basic Modul

•

Workpiece:

Cylinder

Taper

Angular Cutter

•

Point:

Plan Face

Chamfer

Corner Radius

Ball Nose

Circular Arc

Double Radius

•

Geometry:

Regulare

2 at Center

1 above Center

Centring Point

3 at Center

•

Cutting Edge Combination:

right helix/right cutting

left helix/left cutting

right helix/left cutting

left helix/right cutting

•

Division:

Equal / unequal division of teeth

•

Production / Regrinding:

Production by different infeed (several

steps)

Regrinding with calculation of removal

length, periphery and rake.

Regrinding, finishing with different

wheels

•

Preparation

Separating

Profile roughing

Profile finishing

Main FlutingMeas.

definition: Point-/ normal cut

Grind direction: Forward / backward

Optional spark out grinding

•

Taper:

Constant angle / constant helix

Regrinding with undefined helix

•

Periphery

Linear relief: 1st/ 2nd /3rd relief angle

Radial relief: Cross-/ longitudinal

Roughing

Grind direction: Forward / backward

Optional spark out grinding

•

Heei:

Grind procedure: Crosswise-/

longitudinal

Production by different infeed (several

steps)

Grind direction: Forward / backward

Optional spark out grinding

•

End Face

Linear relief grinding

Hollow grinding

•

Chamfer Clearance/Chamfer

Linear relief: 1st/ 2nd /3rd relief angle

Grind. direction: Forward / backward

Optional spark out grinding

•

Gashing

Grinding procedure:

Recessing / Interpolation

Radius at entry and exit

Variable aperture angle

•

Notching:

Radius at entry and exit

Variable entry- and aperture angle

•

Profile Simulation:

Simulation of intersection at all

operations

Wheel/workpiece-simulation

Machining simulation

•

Variably Helix of Fluting:

“tool-kit PROFESSIONAL ... die Software für den Profi”

MODUL ENDMILLS

CONTACT

Email:

Phone: